What Functions Do Forklift Trucks Serve in Materials Handling?

Here we briefly describe what function the following classifications of equipment serve in materials handling:

Forklift Trucks

The most common type is a forklift truck. This truck can be driven up to the precise location of the load or racking and the tynes overhang from the front of the machine with no straddle legs or arms.

It means a reach function is not required because it brings itself to straightforward operation. Forklift trucks are available as petrol/LPG (dual fuel) and diesel powered options. They have driver cabs and can have different attachments fitted to them to suit different load applications.

Reach Trucks

Reach trucks are intended largely for warehouse operations. They offer ultimate lift height with exceptional manoeuvrability. The forks are designed to ‘reach’ out outside the stabilising legs and thus ‘reach’ into racking. While still operating in very tight working environments, reach trucks can lift to great heights (above 10 metres).

The straddle legs and batteries in a reach truck counteract the requirement for any counterbalancing weight within the truck build. A few reach truck manufacturers design products with a tilt-able cab mechanism to create a more comfortable position for an operator to view loads at a height. On the other hand, some other manufacturers keep a very open overhead guard, as they think it is simply not required. To increase visibility, reach trucks can be fixed with cameras on the fork carriage, which pass on a signal down to an LCD screen in the cab to assist navigation. These systems can be wireless or wired, but as per our experience, wired systems are more dependable as they are not vulnerable to obstruction from outside sources like broadband routers. Reach trucks are made for indoor use and they do an excellent job.

Hand Pallet Trucks

Hand pallet trucks are non-powered pedestrian operated pallet movers that can move palletised loads usually up to 2,000kg in weight. They are easy to use with the operator sliding the forks into the pallet and by pumping the handle to lift the forks from the ground, and moving the load through the handle. The front wheels are fitted inside the end of the forks, and as the hydraulic jack is lifted, the forks are divided vertically from the front wheels, forcing the load upward till it clears the ground.

The pallet is raised adequately to clear the ground for subsequent move. Lencrow Materials Handling has available now a huge range of powered pallet trucks that will cover the needs of all Australian businesses.

Various types of hand pallet trucks are available:

The above mentioned are just a few of the forklift trucks from a large range.

Lencrow Materials Handling is completely an Australian owned and family operated business since 1976 providing a range of forklifts from top brands for the different material handling requirements. You can buy new or used forklifts outright or get forklifts on rental basis per your business requirements from Lencrow.

Different Types of Material Handling Equipment Used in Warehouse

Any business which requires bulk manufacturing, distribution and storage of industry material may view warehouse operations as an overwhelming challenge.

The processes followed and approach taken inside the warehouse greatly impact the outcome of your business. As such, many businesses are unaware of the methods and equipment they require to increase the speed, efficiency and productivity of material management. Such factors are a much bigger part of how the business will perform in the competitive market.

The modern warehouse offers a range of challenges for operators. Such challenges not only impact the running of the warehouse but can also have negative implications for production and delivery, if the equipment used is inadequate.

Materials handling equipment must suit the size of the facility. To ensure you get it right, you must know what you will be moving, and how much of it. Then, we can help you find the forklift to suit your needs.

Need a forklift for your warehouse? Contact us on 1300 198 308 or enquire online today.

Forklifts used in warehouses

Pedestrian operated forklift

Pedestrian operated forklifts come in a range of sizes and lift heights. These units are suitable for the smaller, independently-operated warehouse. These forklifts don’t require the operator to have a license, and they offer features such as electric power steering and a side shift to be more user-friendly.

Counterbalance forklifts

Counterbalance forklifts are designed with the tines in front, and driver situated on the unit behind. These units come in many sizes and lift heights, and are available in petrol, LPG, diesel, and electric.

However, counterbalance forklifts require larger warehouse aisles for turning.

Reach trucks

Reach trucks are the most common units used in larger warehouses mainly because they have the advantage of working in narrow aisles and offer lift heights of up to 14 meters. Reach trucks are battery-electric units.

Reach trucks include turret trucks, side loaders, order pickers, cranes and pallet jacks. It’s imperative that you request a consultation with a specialist to find the best truck to suit your needs.

Contact the experts at Lencrow Forklifts, or fill out one of our online enquiry forms today to find a reach truck to suit your business.

Bulk materials handling

If you’re handling challenging materials such as the storage of solid and liquid items, it’s important that you employ safe methods to adequately transfer these products to and from the storage medium. Today, we have many ways to safely execute this by using pumps, vacuums, mechanical transfers, and gravity loads.

Some of the equipment used for handling bulk materials includes tanks, silos, pumps, augers, conveyors and vacuums.

Storage equipment used in warehouses

The most productive warehouses are those which have efficient layouts. To achieve this, you must plan – so look at what you will be storing, the number of goods, and the space available. After you have planned, then you can identify how to store the goods.

Using a simple mechanism of shelving and sectioning, storage equipment makes it possible for various materials to be rearranged, while avoiding major accidents or potential delays. Storage equipment is also one way of ensuring the operational area of the warehouse remains clean, organised and clutter-free.

Racking equipment

Racking equipment comes in many forms. Standard palettes broadly suit most goods, whereas counterbalance racks are used for goods that require a longer reach length. Other forms include drive-in, double deep, vertical carousel, and gravity load. Your options are guided by your needs.

Warehouse traffic flow is a very important factor, as a planned flow ensures a safer work environment whilst improving the efficiency of operation.

Need equipment?

If you’re in need of materials handling equipment suitable for warehousing, consider reputation when searching for an industry services provider. It’s likely that while conducting your research, you’ll come across multiple distributors and suppliers. However, be cautious with your choice, as whether you are purchasing or hiring equipment, the decision is one which has lasting implications, either positive or negative.

As Australia’s largest independent forklift supplier, Lencrow Forklifts is among the rare front-runners when it comes to delivering industry-specific equipment solutions across assorted businesses. Through years of practice and commitment to make a positive difference to your business, Lencrow Forklifts has created a strong reputation via building strong and long-lasting relationships with customers.

Apart from quality, Lencrow Forklifts also offers convenience and flexibility when hiring or buying material handling equipment. With us, you can hire forklift or buy new, used forklift in order to optimise your warehouse budget.

Get in touch with the experts at Lencrow Forklifts today. Fill out an online enquiry form, or call us on 1300 516 436

Lencrow can now supply Lowry Forklifts

Lowry forklifts built in Canada are a part of the Manitex Liftking Group who also build Liftking rough terrain forklifts .

Lowry forklift are build to work in confined spaces offering lifting capacities of 11000 to 23000kgs all less than 1500mm wide. When it comes to confined spaces and heavy lifts Lowry has the machine. Lowry units all come with electronically controlled Dana three speed transmissions and have option of LPG and diesel engines. The units are all fitted with cushion tyres to ensure maximum stability for foot print.

Mark Aldrovandi International Sales Manager of Liftking says “We are very happy that Lencrow will be offering both Lowry and Liftking products in Australia. We have supplied a lot of the Lowry machines in Canada and the USA and they are proving our customers with very reliable products in their manufacture facilities. We have put a lot of effort into making these units driver friendly while still offering robust design.”

The Lowry units are suited in many manufacturing situation where both size and large capacity lift is required. These units are also ideal in the machinery relocation industry where getting equipment out of existing sites that offer little to no space but still require the muscle to get the job done.

Ross Grassick General Manager of Lencrow says “We have been looking to offer a range of equipment like Lowry for some time. We have found it hard to get a product that can offer a built to requirement unit. Lowry offers us with the ability to make changes in the build to make the unit more suitable for the application. These could be making the unit suitable for container entry or custom build masts and carriages for special needs.”

The Lowry range all offers wide view mast and wet brakes in all models. For more information on the Lowry range call Lencrow on 1300 516 436 or visit them at www.lencrowforklifts.com.au

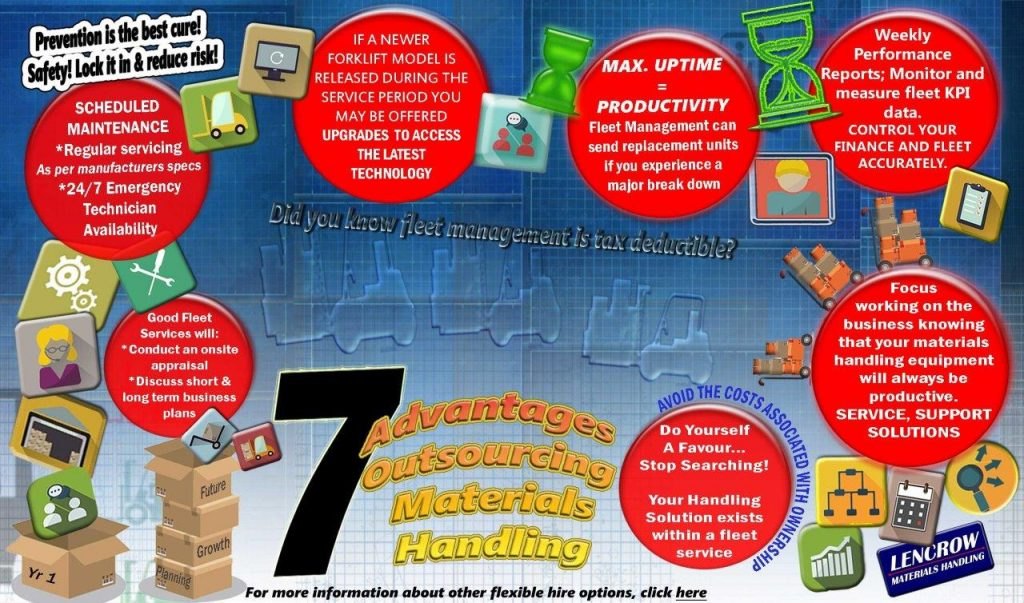

7 Advantages of Outsourcing Materials Handling Management

Businesses with large fleet requirements, vehicles and equipment, know that the cost involved with owning and maintaining each unit is costly. What are the advantages of outsourcing fleet management? Fleet companies already own the equipment and will loan fleets and maintain each unit for a contracted long term period. The major benefit for business is the transparent financial forecasts for the term of the contract with the guarantee each unit in the fleet is serviced and maintained.

What are the other advantages to outsourcing a fleet for your business? Here are 7 reasons why you would consider this service for your business:

1. Customise your fleet to maximise the workflow of goods with an experienced consultant

Fleet management is a tailored service that’s specifically designed to meet your business’s handling requirements. Fleet management isn’t a one size fits all approach and your workspace can achieve increased productivity when the right materials handling equipment in place. Fleet consultants arrange to visit your workplace and appraise your space, handling needs and discuss short and long term expectations to develop the best fleet strategy for your operation. A major advantage when negotiating a long term contract is finding which service suits your business’s short and long term goals before you commit to a contract.

2. Guaranteed technical assistance when you need it:

Preventative maintenance plans reduce the likelihood of major breakdowns. Scheduled services reduce the risk of major faults occurring which can be expensive, time wasting as well as dangerous to operators and others in the workplace. Fleet management services will keep every fleet unit recorded and notify you when fleet units are due for a service. Regular services should be at least every 12 months or as per the manufacturer’s standards. Book services before they’re overdue, secure your qualified technician and plan to stay productive in advance around it.

Companies who manage fleets know that mechanical issues do occur unexpectedly. Fleet services generally offer emergency assistance, some with 24/7 availability, and dispatch a technician to repair the unit so you don’t experience long downtime periods.

3. Upgrade to newer models if they change:

When you agree to a fleet contract you will generally begin the term of the agreement with new equipment. The advantage of the fleet provider supplying you with new equipment is that their own qualified service technicians maintain each units. Ask your forklift management service if they offer upgrades when new models are added to their fleet.

Ensure you review your fleet plan throughout the contract. If handling volume change or floorplans revised speak to your service manager and make sure your fleet plan is still maximising productivity.

4. Maximum productivity:

Time is money, money is time! This is true for every business and if your operation relies on maintaining strict schedules you need a plan B in the event of a major breakdown. If you have a forklift management service, you have a plan B! You will be supplied with a replacement unit while the other forklift is repaired offsite.

5. Detailed fleet reports to monitor performance:

Fleet performance is measured using various KPI that provide an accurate cost and productivity scope to analyse each unit. Quantify the cost of the fleet with certainty. KPI’s include; individual hour readings, inactivity, cost of parts, cost of labour, downtime, etc.

6. Plan to fail! Hire an experienced management service to take all the service responsibility:

Spend time working on your business, not in it. Choose a fleet management service you are confident will provide the right solution for your business. Secure a service to be available when you need it and supports the long term growth of the business.

7. Plan for the future:

Fleet management is a long term arrangement. Find an established service provider that can fulfil all of your materials handling needs for the full term of the contract. Careful planning can safeguard your business’s plans for the future.

Did you also know that fleet management is tax deductible for some businesses? That’s a bonus advantage to consider. Consult your accountant to see if your business qualifies.

Fleet management is one of many long term solutions businesses can consider to hire materials handling equipment. Lencrow Materials Handling is one of the original forklift hire companies in Sydney. Lencrow is Australian owned and family operated with a range of services tailored to suit the needs of local business. Would you like to know more? Explore Lencrow’s fleet online at http://www.forkliftsrental.com.au/ or phone 1800 FORK HIRE (1800-3675-4473) for personalised service about the best forklift hire for you.

How to clean an electric forklift?

We aim to offer practical and informed advice regarding materials handling equipment for owners operators and website visitors. Out live chat service attracts a range of questions from internet visitors including sales requests, opportunities to interpret spare parts information and general forklift enquiries. We get hear from you the kinds of information about forklifts that you want to know – from the most simple to some that are a little complex. Join our newsletter to find out our recommendations for the questions asked by you. We encourage you to keep on asking us new questions so we can build a comprehensive portal of tips for you to reference at any time.

What’s the best way to keep an electric forklift clean? It is really easy to make a costly mistake if you’re not sure. Great question! Credits go to one of our recent online chatter’s – Thanks Carly, in Victoria.

Question: “How do you clean an electric forklift?”

Answer: Use compressed air, not water.

Air compressors are the only way to keep an electric forklift clean on the outside. If you use water it can impact the forklift’s electrical components causing extensive damage and electrical shortages. Exposing an electric forklift to water causes electrical failure, power shortages, broken seals and inevitably corrosion. Using the right amount of air pressure, easily created by using an air compressor, you will be able to remove most debris and dirt easily off the outside of your forklift.

Electric forklifts are designed to be water resistant – not waterproof! Please remember they are cannot be operated in the rain or exposed to large amounts of water.

We did some research on prices at local retailers and air compressors can be purchased for as little as $100, which is cheaper than the cost of a call out fee for a service technician to repair any water-damaged components. Most forklift servicing vehicles are fitted with air compressors and technicians can do this for you if you have them coming to your site – just ask!

Electric Battery Maintenance: If you require the battery in your electric forklift cleaned we recommend having it inspected by an authorised person. Batteries are expensive to replace if they are not maintained correctly. Your local authorised service centre will have the right equipment on site to carry out the correct battery maintenance for you. Call your local service centre for more information about this service.

Thanks to Carly for the question! Here’s a link on how to pressure clean an electric forklift correctly. Feel free to have a chat to us if you have any questions you’d like answered.